Difference between revisions of "Baglivo 2022 Abstract Bioblast"

Tindle Lisa (talk | contribs) |

|||

| (7 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:Bioblast2022 banner.jpg|link=Bioblast_2022]] | [[File:Bioblast2022 banner.jpg|link=Bioblast_2022]] | ||

{{Abstract | {{Abstract | ||

|title=[[File:BaglivoE.jpg|left|100px|Baglivo Eleonora]] <u>Baglivo Eleonora</u>, Cardoso LHD, Cecatto C, Gnaiger E (2022) Statistical analysis of instrumental reproducibility as internal quality control in high-resolution respirometry. Bioblast 2022: BEC Inaugural Conference. <br>[[ | |title=4.1. '''«10+5»''' [[File:BaglivoE.jpg|left|100px|Baglivo Eleonora]] <u>Baglivo Eleonora</u>, Cardoso LHD, Cecatto C, Gnaiger E (2022) Statistical analysis of instrumental reproducibility as internal quality control in high-resolution respirometry. '''Bioblast 2022: BEC Inaugural Conference.''' In: https://doi.org/10.26124/bec:2022-0001 <br>[[Baglivo_2022_BEC|»''Bioenergetics Communications''«]] [[File:WatchThePresentationYoutube_icon.jpg|200px|link=https://www.youtube.com/watch?v=mNSu-hY3hUg&t=15s|»''Watch the presentation''«]] | ||

|info=[https://wiki.oroboros.at/index.php/Bioblast_2022#Submitted_abstracts Bioblast 2022: BEC Inaugural Conference] | |info=[https://wiki.oroboros.at/index.php/Bioblast_2022#Submitted_abstracts Bioblast 2022: BEC Inaugural Conference] | ||

|authors=Baglivo Eleonora, Cardoso Luiza HD, Cecatto Cristiane, Gnaiger Erich | |authors=Baglivo Eleonora, Cardoso Luiza HD, Cecatto Cristiane, Gnaiger Erich | ||

|year=2022 | |year=2022 | ||

|event=[[Bioblast 2022]] | |event=[[Bioblast 2022]] | ||

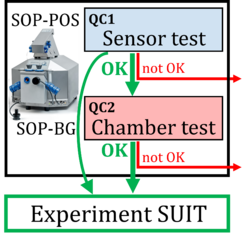

|abstract= | |abstract=[[File:Baglivo 2022 MitoFit QC graphical-abstract.png|250px|right]] | ||

Evaluation of instrumental reproducibility is a primary component of quality control to quantify the precision and limit of detection of analytical procedures. A pre-analytical instrumental standard operating procedure (SOP) is implemented in high-resolution respirometry consisting of: (''1'') a daily SOP-POS for air calibration of the polarographic oxygen sensor (POS) in terms of oxygen concentration ''c''<sub>O<sub>2</sub></sub> [µM]. This is part of the ''sensor test'' to evaluate POS performance; (''2'') a monthly SOP-BG starting with the SOP-POS followed by the ''chamber test'' quantifying the instrumental O<sub>2</sub> background. The chamber test focuses on the slope d''c''<sub>O<sub>2</sub></sub>/d''t'' [pmol∙s<sup>−1</sup>∙mL<sup>−1</sup>] to determine O<sub>2</sub> consumption by the POS and O<sub>2</sub> backdiffusion into the chamber as a function of ''c''<sub>O<sub>2</sub></sub> in the absence of sample. Finally, zero O<sub>2</sub> calibration completes the sensor test. | Evaluation of instrumental reproducibility is a primary component of quality control to quantify the precision and limit of detection of analytical procedures. A pre-analytical instrumental standard operating procedure (SOP) is implemented in high-resolution respirometry consisting of: (''1'') a daily SOP-POS for air calibration of the polarographic oxygen sensor (POS) in terms of oxygen concentration ''c''<sub>O<sub>2</sub></sub> [µM]. This is part of the ''sensor test'' to evaluate POS performance; (''2'') a monthly SOP-BG starting with the SOP-POS followed by the ''chamber test'' quantifying the instrumental O<sub>2</sub> background. The chamber test focuses on the slope d''c''<sub>O<sub>2</sub></sub>/d''t'' [pmol∙s<sup>−1</sup>∙mL<sup>−1</sup>] to determine O<sub>2</sub> consumption by the POS and O<sub>2</sub> backdiffusion into the chamber as a function of ''c''<sub>O<sub>2</sub></sub> in the absence of sample. Finally, zero O<sub>2</sub> calibration completes the sensor test. | ||

| Line 18: | Line 18: | ||

:::: This work was part of the Oroboros [[NextGen-O2k]] project, with funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement nº 859770. | :::: This work was part of the Oroboros [[NextGen-O2k]] project, with funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement nº 859770. | ||

== List of abbreviations, terms and definitions - MitoPedia == | == List of abbreviations, terms and definitions - MitoPedia == | ||

| Line 26: | Line 23: | ||

{{Labeling | {{Labeling | ||

| | |event=A4 | ||

|articletype=Abstract | |articletype=Abstract | ||

}} | }} | ||

Latest revision as of 13:10, 4 August 2022

| 4.1. «10+5» Baglivo Eleonora, Cardoso LHD, Cecatto C, Gnaiger E (2022) Statistical analysis of instrumental reproducibility as internal quality control in high-resolution respirometry. Bioblast 2022: BEC Inaugural Conference. In: https://doi.org/10.26124/bec:2022-0001 »Bioenergetics Communications« |

Link: Bioblast 2022: BEC Inaugural Conference

Baglivo Eleonora, Cardoso Luiza HD, Cecatto Cristiane, Gnaiger Erich (2022)

Event: Bioblast 2022

Evaluation of instrumental reproducibility is a primary component of quality control to quantify the precision and limit of detection of analytical procedures. A pre-analytical instrumental standard operating procedure (SOP) is implemented in high-resolution respirometry consisting of: (1) a daily SOP-POS for air calibration of the polarographic oxygen sensor (POS) in terms of oxygen concentration cO2 [µM]. This is part of the sensor test to evaluate POS performance; (2) a monthly SOP-BG starting with the SOP-POS followed by the chamber test quantifying the instrumental O2 background. The chamber test focuses on the slope dcO2/dt [pmol∙s−1∙mL−1] to determine O2 consumption by the POS and O2 backdiffusion into the chamber as a function of cO2 in the absence of sample. Finally, zero O2 calibration completes the sensor test.

We applied this SOP in a 3-year study using 48 Oroboros O2k chambers. Stability of air and zero O2 calibration signals was monitored throughout intervals of up to 8 months without sensor service. Maximum drift over 1 to 3 days was 0.06 pmol∙s−1∙mL−1, without persistence over time since drift was <0.004 pmol∙s−1∙mL−1 for time intervals of one month, corresponding to a drift per day of 0.2 % of the signal at air saturation. Instrumental O2 background -dcO2/dt was stable within ±1 pmol∙s−1∙mL−1 when measured at monthly intervals. These results confirm the instrumental limit of detection of volume-specific O2 flux at ±1 pmol∙s−1∙mL−1. The instrumental SOP applied in the present study contributes to the generally applicable internal quality control management ensuring the unique reproducibility in high-resolution respirometry.

• Keywords: high-resolution respirometry HRR; polarographic oxygen sensor POS; air calibration; instrumental background; reproducibility; limit of detection; internal quality control IQC; standard operating procedure SOP

• O2k-Network Lab: AT Innsbruck Oroboros

Affiliations and support

- Oroboros Instruments, Innsbruck, Austria

- This work was part of the Oroboros NextGen-O2k project, with funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement nº 859770.

List of abbreviations, terms and definitions - MitoPedia

Labels:

Event: A4